Table of Contents

What is a Brushless DC Pump?

Brushless DC Pump is a kind of dc water pump that use a bldc motor to drive the impeller on its rotor to pressurize fluid and transport liquids like water, air, oil, etc. For its high-efficiency, long life span and quiet advantages brushless dc water pump is widely used in various equipment as a liquid transport functional component.

How Does a Brushless DC Pump Work?

Before running the brushless DC water pump , it need to fill the pump chamber with water to eliminate the air in it. After connecting the DC power supply to start the water pump motor, the motor controller controls the direction and magnitude of the current to generate a rotating magnetic field between the permanent magnets and windings on the rotor, which in turn drives the permanent magnets (rotor) to rotate. The impeller on the rotor begins to rotate at high speed with the rotor under the action of electromagnetic force, thereby driving the water between the blades to rotate at high speed with the blades. The impeller rotates at high speed to produce centrifugal force on the water. At this time, the water is thrown out from the center of the impeller and obtains kinetic energy. At the same time, it leaves the outer edge of the open impeller at a high speed and then enters the pump head volute.

In the volute of the pump head, due to the bending and elongation of the flow channel, the speed of the water is reduced and the kinetic energy is converted into pressure energy, and the water is pushed into the drain pipe by high pressure. Since the impeller continues to operate along with the motor, a negative pressure is generated in the pump chamber, so water is continuously sucked into the pump chamber under the action of atmospheric pressure, and then continuously discharged out of the pump chamber and pump casing through the work of the impeller. This is How the brushelss dc pumps working principle.

Learn more about brushelss dc pump work: What Is a Brushless DC Water Pump and How Does It Work?

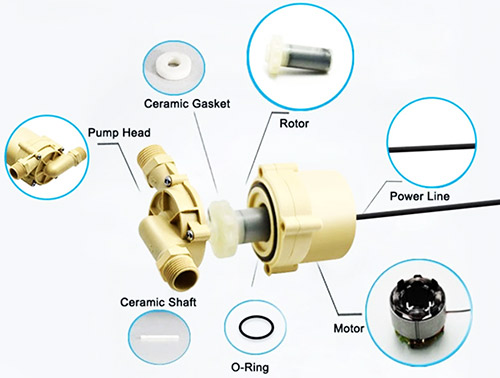

Brushless DC Pump Structure

Permanent Magnet

The stator of a brushless DC pump is generally made of rare earth permanent magnet materials, which have high coercive force and good anisotropy in the direction of the magnetic field. Demagnetization will not occur when the same poles are close together, and they are good magnetic field sources.

Shaft

As brushless DC magnetic pump works by driving the rotor to rotate through an energized coil, in order to keep the rotor rotating smoothly and noiselessly, people usually use high-precision and high-performance ceramic shafts to produce pumps, which effectively reduces rotational resistance and noise.

Bearing

The sliding bearing material of brushless DC water pumps generally uses engineering plastic steel (POM) or ceramics. Because plastic steel (POM) and ceramics have good heat resistance, corrosion resistance and friction resistance. Therefore, the bearings of brushless DC water pumps are generally made of engineering ceramics.

Rotor

The brushless DC water pump rotor is usually injection molded from magnets and impellers.

Impeller

What Types of Brushless DC Pumps Are There?

Brushless DC Motor Water Pump

Brushless motor DC water pump is mainly composed of brushless DC motor, impeller, pump shell and pump chamber. The shaft of the motor is connected to the impeller. As there is a gap between the stator and the rotor of the motor, there is a possibility that water can penetrate into the inside of the motor when the water pump is working for a long time. In this cae it increases the possibility of short circuiting the windings and causing damage to the motor. However, the cost of this type of water pump is relatively low and the efficiency is high.

Brushless DC Water Pump

Unlike brushed DC motors that rely on carbon brushes for commutation, brushless DC motor use circuit programs or electronic components for commutation, so, there is no problem of carbon brush commutation wear which lead to a greatly limited working lifespan. Therefore, working lifespan of brushless DC water pump is much longer than that of the brush motor water pump and the brushless motor water pump. And as the stator part and the rotor part are completely isolated, also the stator and circuit board parts are potted with epoxy resin, pump’s waterproof performance is very high and can be used as a submersible pump. At the same time, the brushless DC pump also has the characteristics of low operating noise, small size, high efficiency, stable performance, adjustable parameters, and wide voltage operation,etc.

Brushless DC Pump VS Brushed DC Pump

As we all know, brushless DC pumps are driven by brushless DC magnetos, while brushed DC water pumps are driven by brush motors. Compares with brushed motors, brushless DC motors have many advantages, such as high efficiency, long life, low noise, etc. Therefore, brushless DC water pumps have more advantages than brushed DC water pumps, mainly in the following aspects:

More Higher Waterproof Performance

Since the brushless DC water pump can achieve closed sealing, the brushless motor water pump completely avoids medium leakage. Also the stator part and the rotor part of the magnetic isolation water pump are completely isolated, and the stator and circuit board parts are potted with epoxy resin, so it can achieve complete with waterproof effect, users can use it as a submersible pump.

More Higher Working Efficiency

As brushless DC motor has more higher efficiency, so brushless dc pump can achieve the same working performance with lower power consumption compared to the brushed DC water pump. Moreover, the brushless pump does not require independent lubrication and water cooling, thus it reducing a large amount of energy consumption.

More Smaller Vibration

Brushless DC pump uses a magneto to drive the rotor to rotate. It has a damping and vibration reduction effect, which can reduce the impact on the water pump like the vibration of a brush motor. It can also reduce the impact on the motor when cavitation vibration occurs in the pump.

More Lower Working Noise

BLDC water pump can adjust various parameters required by the user by adjusting the number of turns of the stator winding, and the electromagnetic noise is very small. Therefore, the operating noise of the brushless DC water pump is much lower than that of a DC brushed water pump with the same performance.

With Overload Protection Function

Water will slip on the ceramic shaft, when the water pump is working in an overload condition, thereby preventing the motor from overheating and protecting the water pump.

Advantages of Brushless DC Pump

As we all know, the brushless DC water pump is built by a brushless DC motor, so it mainly has the advantages of portability, small size, high efficiency, low price, low operating noise, long service life, and high reliability. Below, we will give you a detailed introduction:

Good Performance

Brushless DC pumps have low repair rate (or even zero), and small in size, high in efficiency, low in consumption, no pollution, environmental protection, high in safety, waterproof, and can work with weak acid, weak alkali, clean water, and many other media.

Low Working Noise

Our brushless dc water pump shaft is made of high-quality materials and has high precision. The operating noise of conventional water pumps is generally not greater than 40dB, and the noise of small-power silent water pumps is even less than 25dB.

Long Working Lifespan

Brushless DC pump can continue to operate for a day of heavy-duty work. Its expected life is at least 30,000 hours, and the design working life can reach 50,000~60,000 hours.

Wide Working Conditions

Brushless DC water pumps made of PPE and PPS materials are suitable for working in indoor and outdoor conditions below 120°C. After optimizing the heat dissipation performance of the motor control circuit, the maximum working liquid temperature of the brushless DC water pump even can reach over 180°C

Multi-function and Working Protections

Brushless DC pump has flexible control method such as PWM, BUS, LIN etc.Electric water pump has multiple working protections such as over temperature, over voltage, over current, etc.

Diversified Custom Designs Available

Brushless DC water pumps are highly customizable, we can custom design and manufacture the pump according to your requirements for the use conditions, operating point performance, functions to meet your special use needs.

How to Choose Brushless DC Pump?

There are many types of Brushless dc pumps in the market. So, what are the principles for customer to purchase a bldc water pump for their application? Generally speaking, when selecting a brushless DC centrifugal pump, the following aspects can be considered:

Flow Head Requirements

To define whether your application is used for liquid delivery, cooling, circulation, water supply, or other purposes. Determine the required flow rate, lift, and working pressure. Maximum flow rate and maximum lift required. The required flow rate and lift are calculated according on the location to which the liquid is delivered, pipe length and height difference.

Liquid Properties:

Determine the nature of the liquid to be pumped, including viscosity, temperature, and corrosion. Different pumps are suitable for different types of liquids.

Power Requirements

Calculate the required power required to ensure that the selected BLDC pump has sufficient driven to meet the application requirements (required flow and lift)

Dimension and Weight of the Pump

Select the appropriate pump size and weight according to the installation space and use requirements. Take into account the pump installation mode and the support structure.

Material Selection:

Select the appropriate material according to the properties of the pump medium. Especially in the treatment of corrosive medium or high temperature medium, should choose corrosion resistance or high temperature resistance materials.

Bearing

The high-quality bearing can guarantee the stable operation of the pump

Performance Curve

View the pump’s performance curve for the performance at different working points to ensure it works steadily in your application.

Control Mode

Consider whether the speed regulation control is needed to adjust the flow rate and head as needed. Brushless DC centrifugal pumps are usually equipped with a controller to control the flow and head by adjusting the speed. Select a pump with an appropriate control mode to meet the specific application requirements.

Reliability and Maintenance

View reliability data provided by the manufacturer and pump maintenance requirements. Brushless DC pumps usually require less maintenance. Understand the reliability and maintenance requirements of the pump, and select the brands and models with good performance and long life. Consider the maintenance of the equipment.

Cost Factor

After considering the above factors, conduct cost analysis. Compare the prices of different models and brands, and choose a cost-effective pump to meet the needs and within the budget.

Manufacturer and Suppliers

Choose a reputable manufacturer or supplier who usually provide good quality products and technical support.

Feedback and Evaluation

Check out feedback and reviews from other users to understand pump performance in practical applications

In short, the selection of brushless DC centrifugal pump needs to consider multiple factors according to the specific application conditions and requirements, to ensure that the selected pump can work stably and reliably, and meet the required flow and head requirements.

What Power Supply Can be Used for Brushless DC Pump?

After selecting the right DC water pump for your product or application, you may run into questions, That is, how to choose the power supply for the water pump? What are the power supply methods for water pumps? In fact, there are many ways to power brushless dc pumps. such as use DC power, adapter power, battery power, or solar panel power. Below we will introduce these power supply methods to you one by one.

Power Adapter

You can plug the power adapter into the home power grid and connect the power wire of the pump to power the brushless DC water pump.

Car Cigarette Lighter Plug

You can directly power the brushless DC water pump by plugging the pump’s power plug into your car’s cigarette lighter plug.

New Energy Vehicle Power Battery

The power output from the power battery of new energy electric vehicles such as household cars or buses is DC power, which can directly power the brushless DC water pump.

Various Dry Batteries

The dry batteries we commonly use are DC. You only need to connect the positive and negative power wires of the water pump to the positive and negative terminals of the battery to drive the water pump to work.

Solar Panel

Solar energy is also a form of energy, and in the wild you can use the DC electricity generated by solar panels to power a brushless DC water pump.

How to Adjust the Speed and water head of Brushless DC Pump?

PWM Speed Adjust

PWM speed regulation is to realize the speed regulation of the DC motor by changing the duty cycle of the PWM signal and thereby changing the average voltage at both ends of the water pump motor, so as to achieve the purpose of adjusting the water head.

Analog Signal 0-5V Voltage Speed Regulation

The speed regulation voltage range of DC motor 0 to 5V speed regulation is 0 – 5V. At 0V, the motor speed is 0, and at 5V, the motor reaches its maximum speed. And as the voltage of 0-5V changes, the speed of the DC motor changes accordingly, which can achieve linear speed regulation between 0-5V, thereby realizing the adjustment of the water pump lift.

Manual Speed Adjust

Manual speed regulation is to lead a speed regulation signal input wire from the motor. After connecting the potentiometer, you can manually realize stepless speed regulation of the motor through it.

Input Voltage Speed Regulation

You can also directly adjust the input voltage of the water pump to adjust the speed of the brushless DC water pump.

How to Use a Brushless DC Pump?

Confirm the Positive and Negative Wire of the Water Pump

Take the brushless DC water pump out of the packaging box and find out the positive and negative poles of the power cord. Generally speaking, the red wire is the positive pole and the black wire is the negative pole. If the power cord of the water pump you buy is of another color, you no need to worry. You can just check the water pump test report that comes with the product to know the positive and negative poles of the power wire.

Confirm the Rated Voltage of the Water Pump

You should check the nameplate of the water pump to confirm the rated voltage of DC the water pump to avoid causing the water pump to fail to perform optimally due to low input voltage, or burning out the motor water pump due to incorrect input voltage.

Filling the Pump Chamber With Water

Before starting the motor, you should take over the water supply and fill one-third of the pump chamber with water or put one-third of the pump body into the water. If the control circuit of this water pump is not sealed with epoxy resin, please do not immerse the entire pump body in water to avoid burning the motor, but the inlet of the pump should be placed in the water.

Connect the Power Supply Correctly

You should connect the positive and negative wires of the water pump to the positive and negative terminals of the power supply to start and run the water pump.

Confirm Water Quality

You should use the bldc water pump to pump clean water, because solids or dirt in sewage with a lot of impurities can easily block the water pump, causing the rotor to get stuck on the shaft, causing the motor to generate more heat, rapidly heating up, and burning the control circuit or coil of the water pump.

Operate Brushless DC Pump According to Specifications

Please operate the pump correctly in accordance with the precautions and usage conditions specified in the specifications provided by the manufacturer from which you purchased the bldc water pump.

Fix the Water Pump

Please try to fix the water pump when it is working and avoid slamming the water pump to avoid affecting the performance of the pump.

Monitor water pump

Please monitor the performance of the pump regularly to ensure its normal operation, and perform regular maintenance according to the recommendations provided by the manufacturer, such as cleaning the pump body and cleaning impurities in the pump chamber.

In addition to strictly following the installation instructions when using a brushless DC water pump, you should also pay attention to the following two points:

Clear Blockages in Time

When the water inlet of a brushless DC water pump is blocked, larger debris in the water will enter the water pump along with the water. It will wear the impeller, pump casing and shaft, etc., seriously affecting the working lifespan of the pump.Therefore, you should clean the debris which in the water inlet and pump cavity in time. You should replace the components such as impellers and shafts in time, if they are damaged beyond repair.

Troubleshooting in Time

If you find a fault with the water pump when using it, you should eliminate it in time and do not let the pump work “sickly”. For example, when you find that the water pump bearings are severely worn, you should replace the bearings in time, otherwise the water pump will consume too much energy and cavitation will occur, which will accelerate the damage of the impeller and directly affect the working lifespan of the water pump. For another example, if you find the pump vibrating violently, you should stop it immediately for inspection. And you should replace the shaft in time, if you find it is deformed.

How to Repair a Brushless DC Water Pump?

Due to the many advantages of brushless DC water pumps, especially the very high reliability, it is generally difficult for brushless DC water pumps to fail except for use failures caused by congenital manufacturing defects. However, if the operator does not follow the usage conditions and correct usage methods of the water pump provided by the manufacturer, and operates the water pump illegally, it is likely to cause the water pump to malfunction. So how to repair the water pump when such a malfunction occurs? Let we explain to you one by one:

Drain the Water from the Pump Chamber

Water pump failure is usually caused by problems with the rotor, shaft, and bearings, so you need to open the pump head cover first to drain away the residual water in the water pump chamber.

Disassemble the Pump in Order

When a water pump fails, you need to disassemble the pump to troubleshoot and resolve the problem. You should disassemble the relevant parts of the water pump in order, please clean the parts one by one after disassembly. And then check them one by one for cracks, damage, wear and other defects. You should replace the damaged parts with new parts, if there are serious defects.

Replace Bearings

Mechanical failures of brushless DC water pumps are generally related to wear of the bearings or spots and looseness on the surface. You can solve the issue by replace these parts with new parts, once discover this situation.

Check Impeller

Check the impeller for cracks and rust holes, and whether the impeller fixing nut is loose, if loose, tighten the screws.

Replace Shaft

Another major cause of mechanical failure of brushless DC water pumps is bending or wear of the shaft. Generally speaking, the bending of the pump shaft should not exceed 0.05mm. If it exceeds this value, the shaft should be repaired or replaced with a new shaft.

Replace Pump Casing

If the pump casing or pump head of the brushless DC water pump is impacted by water hammer or the accumulated water is not discharged in time in severe cold winter, the pump casing may rupture. At this time, you should repair it or replace with new parts.

How to Clean a Brushless DC Pump?

You should take care to ensure not to damage the pump or affect its performance when do this work. Here are some general steps to clean the brushless DC pump:

Disconnect Power

First, ensure that the pump is disconnected to avoid any risk of shock or damage. Then remove the pump from the water system.

Remove the Pump

If possible, you can carefully remove it use methods specified in the instructions and remove them into its components. Notice and remember the location of the components and how to reassemble them.

Clean the Outside

You can use mild soapy water and a soft brush or cotton cloth to carefully and gently clean the outside of the pump. Avoid the use of corrosive or worn cleaners to damage the shell or label.

Clean the Interior

If it is necessary to clean the internal parts of the pump, make sure to use the appropriate tools and methods, according to the instructions, generally speaking, use a clean liquid, such as distilled water or cleaning liquid, gently clean the interior, but do not allow the electronic components to touch the water. Use an air pressure or soft brush to remove any dirt or particles.

Disinfection

Disinfect the pump head cover and rotor with disinfectant to ensure thorough cleaning.

Dry the Pump

Thoroughly dry all parts of the pump to ensure no residual moisture. An air compressor, hair dryer or air blow gun can be used to accelerate drying.

What Are the Common Faults of Brushless DC Pump and How to Repair?

Brushless dc pump is one of the important components of the water transfer , lift and circulation system. However, brushless dc pump some times does not work normally and may malfunction during the operating period after a long-term operation. What reasons cause these faults and How to repair these faults? We will answer you as below:

Can Not Start

Check whether the power supply is normal, the power cord is loose or short circuit, and the motor is damaged. If not, it could be the electronic controller. The electronic controller should be replaced right now.

Failure to Work after Startup

It may be motor damage or excessive gap between the rotor and the pump body. At this time, you need to replace the motor or adjust the gap between the rotor and the pump body.

Big Working Noise

The bearing may be damaged or the gap between the rotor and the pump body is too large, which needs to replace the bearing or adjust the gap between the rotor and the pump body.

Less Water Pump Output

It may be scaling inside the pump head or filter blockage. At this point, the pump head and filter should be removed for cleaning.

Excessive Pump Water Output

Maybe the internal seal of the pump head is damaged or the filter is not installed. At this point, it is necessary to replace the internal seal of the pump head or reinstall the filter.

It should be noted that safety operating procedures should be followed to ensure that the power is disconnected. In addition, if the cause of the fault cannot be determined or cannot be repaired, professionals should be contacted for repair.

How to Maintain a Brushless DC Water Pump?

You should perform the following maintenance work after operating the brushless DC pump for a period of time, or not used for a long period of time.

Drain the Remaining Water in the Pump Chamber

You should drain the water pump chamber and the remaining water in the pipes in time after each use of the pump.

Clean Pump

You can disassemble and clean the DC water pump and pipeline, if it is easy to disassemble.

Check All Components

After using the water pump, you should check whether there are cracks or small holes in the water pump impeller, and whether the screws on the pump head are loose. If the above phenomena occur, you they should repaire or replace them. Check the gap at the impeller anti-friction ring. You should repaire or replace it, if it exceeds the specified value.

Seal the Outlet and Inlet of the Pump

You should seal the outlet and inlet of the water pump with a cover plate to prevent debris from entering, when the water pump and pipeline are not disassembled,.

Prevent Screws from Rusting

You should remove all the screws and clean them with a wire brush, and lubricate them before installation on the pump to prevent the screws from rusting, when the brushless DC pump is not used for a long time. By doing so, prevents the screws from rusting and cannot be removed when the water pump is not used for a long time. This will also cause the pump head cover to be unable to be opened to repair the pump when the water pump’s sealing ring or shaft or impeller fails.

Learn more about maintain brushless dc pump:How to Maintain a Brushless DC Water Pump?